The Future of Precision Manufacturing: Trends, Challenges, and Opportunities

Introduction to Precision Manufacturing

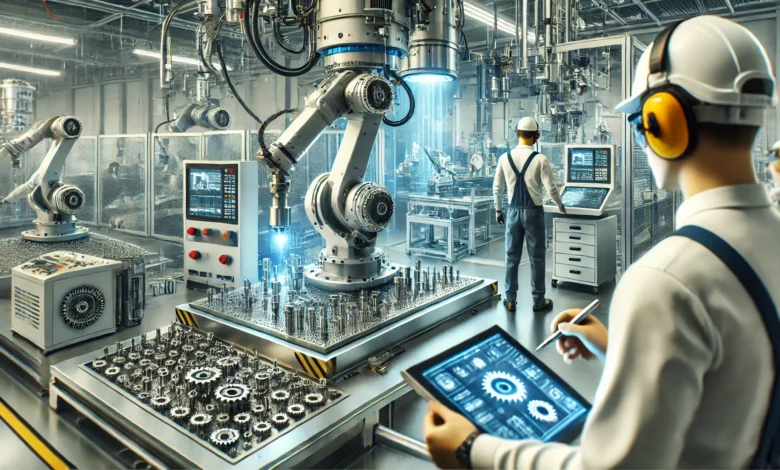

Precision manufacturing is vital in aerospace, healthcare, and electronics, producing accurate components with strict tolerances using advanced techniques. As industries demand more efficient, defect-free parts, its importance grows.

Companies providing fabrication services Troy OH, play a pivotal role in driving this sector forward. Their expertise in crafting exacting products not only supports advanced innovation but also ensures businesses remain competitive in a rapidly evolving marketplace. From medical implants to intricate electronic parts, the reach and impact of precision manufacturing extend across virtually every aspect of modern life.

Driving Forces Behind Modern Manufacturing

Today’s manufacturers are driven by automation, robotics, and advanced data analytics, shaping production with increased safety, consistency, and productivity. This shift to smart manufacturing responds to rising consumer demands, shorter product cycles, and the need for flexible operations. Industry 4.0 accelerates this trend by integrating IoT and AI for real-time monitoring, continuous improvement, and enhanced insights. The outcome is a synergy of human skill and digital efficiency, raising quality and output standards.

Common Challenges Manufacturers Face

Despite advances, manufacturers face ongoing challenges requiring resilience and adaptability. Supply chain disruptions persist due to economic volatility, geopolitical tensions, and natural disasters, causing material shortages, delays, and supplier uncertainties, which force reevaluation of sourcing strategies. Additionally, a skilled talent shortage exists as automation and digitalization grow, widening the skills gap. Maintaining precision at scale, especially in high-volume scenarios, remains a challenge, necessitating continual investment in quality assurance and standards.

Opportunities in Sustainability and Green Manufacturing

Amid environmental concerns, precision manufacturing shifts toward sustainability. Companies adopt eco-friendly materials, conserve energy, minimize waste, and reduce environmental impact. These efforts enhance brand reputation and regulatory compliance. Innovators invest in renewable energy, closed-loop systems, and digital tracking for resource management. Forbes states sustainability now drives industry innovation, aiding material discovery, workflow improvement, and regulatory alignment.

Digital Transformation and Data-Driven Production

Digital transformation is revolutionizing manufacturing by integrating big data and analytics for predictive maintenance, process optimization, and smarter decisions. Data insights reduce downtime, extend equipment lifespan, and improve monitoring. Digitization enhances transparency and traceability, boosting product quality and compliance. Forward-thinking firms see benefits like faster time-to-market and greater agility. McKinsey & Company reports real-world examples of digital workflows reshaping the industry.

Strategies for Workforce Development

Adapting to technological change demands strong workforce development. Practical training in emerging tech—like additive manufacturing, robotics, and data analytics—is key to closing skills gaps. Companies partner with institutions to build talent pipelines and practical skills. Promoting continuous learning keeps employees adaptable and innovative during industry shifts. Upskilling and cross-training enable organizations to respond flexibly, lowering risks and boosting growth and retention.

Reimagining Supply Chains for Resilience

Supply chain resilience is emerging as a critical focus for manufacturers. Leading organizations are adopting best practices such as scenario planning, diversification, and risk modeling to mitigate the impact of disruptions. Leveraging relationships with local and regional suppliers helps cushion against uncertainties in international trade.

Advanced digital solutions and predictive analytics enable businesses to forecast potential supply interruptions and adjust proactively, thereby reducing the likelihood of bottlenecks. Investing in supply chain innovation and agility is crucial for sustaining operational stability and ensuring customer satisfaction.

What Lies Ahead: Predictions for Precision Manufacturing

The horizon for precision manufacturing is marked by rapid change and breakthroughs. The adoption of 3D printing and additive manufacturing promises faster prototyping, lighter components, and more design options. As these grow, manufacturers can customize products more efficiently and meet niche market demands. However, challenges like cybersecurity, regulatory issues, and ethical concerns with automation and AI remain. Success will require strategic partnerships, ongoing reskilling, and a strong focus on innovation.

Conclusion

Precision manufacturing is at a crossroads of technological advancement, workforce transformation, and sustainability. Embracing smart manufacturing, digital innovation, and sustainable practices enables businesses to thrive, even amid uncertainty. By remaining adaptable and prioritizing continuous improvement, leaders can ensure long-term relevance in the vibrant world of modern manufacturing.